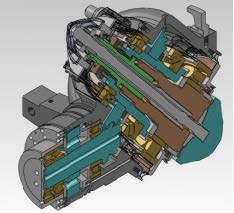

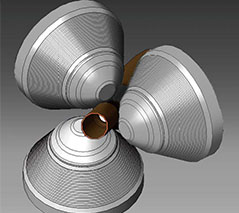

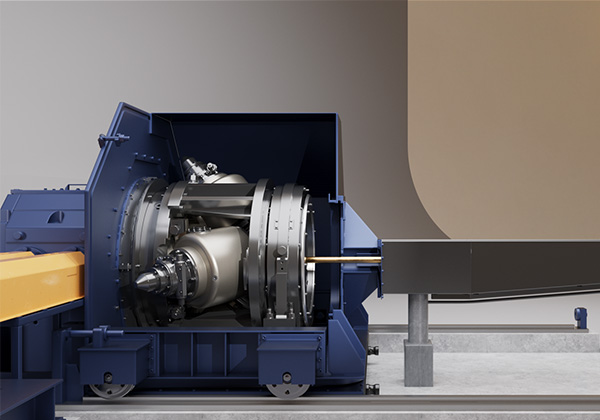

The Planetary Rolling Mill is specially designed to reduce copper casting shells into mother tube,suitable for downstream cold drawing.This method of planetary rolling of copper tube can achieve an improved reduction greater than 90%;at a continuous feeding speed up to 1.9m/minute.The casting shell does not require any preheating,as massive deformation heat increases the material temperature in the rolling zone up to 700-800℃. Recrystallization occurs during this operation, allowing mother tube to have the perfect grain structure for the downstream cold drawing process. The planetary rolling mill is the key piece of

equipment in “CAST & ROLL” technology.

FEATURES

◆ Low energy consumption

◆ Extremely high yield

◆ High efficiency

◆ Minimized eccentricity

◆ Heavy coil weight

◆ Low operating cost

◆ Reduced manpower requirements

|

ITEM |

DATA |

|

Casting Shell OD (mm) X Wall (mm) |

90~102X24~26 |

|

Casting Shell Length (m) |

20-25 |

|

Max Feeding Speed (m/min) |

1.9 |

|

Output tube OD (mm) X Wall (mm) |

48~60X2.3~3.0 |

|

Max Coil Weight (kg) |

1200 |

|

Max Yield (%) |

99 |

|

Max Capacity (MT/h) |

4.5 |

|

Power (kw) |

1400 |